One of the most exciting aspects of working with the IoT is that it’s a cross disciplinary field. To build a successful product, you and your team need to be familiar with software and hardware design. For some folks this can be intimidating, especially for those coming from a non-hardware background.

Fortunately, there are a number of hardware ecosystems designed for rapid prototyping that can help you ease your way into working with hardware and building a proof of concept.

In this article you’ll learn a bit of the history of the approach and how you can apply it to your work building IoT prototypes.

Prototyping Gets Rapid

Broadly speaking, rapid prototyping is a popular method by which to build proof-of-concepts quickly and cost effectively. It’s a process that’s used today by large companies but it’s also incredibly effective for individuals like you and me.

Rapid prototyping first gained popularity in the field of additive manufacturing — specifically with the work of Hideo Kodama and Charles Hull on Selective Laser Sintering (SLS) 3D printing. In some circles the only real definition of the term “refers to the rapid production of models and prototypes using CAD data.” But rapid prototyping isn’t just for the 3D printer and manufacturing crowd.

Unsurprisingly, other fields of engineering and design found application in their fields, but with unique twists. This is especially true in the case of IoT hardware prototyping, which has the luxury of an entire small industries around making modular electronic ecosystems. But I get ahead of myself.

Iterate, Iterate, Iterate

In brief, rapid prototyping is all about iterating through a list of steps to help you stay on track with the goal of the work: to have a minimum viable prototype. You'll see various terms and descriptions for each step, but it doesn't really matter what they are called. It just matters that you're following the same method of reviewing and refining and repeating that process.

- Prototype

- Review

- Refine

- Repeat steps 2-4 until you’re satisfied

The key takeaway with all of this is that you should not strive to make the perfect prototype in one go. Incremental, iterative, and done in quick bursts with considered review and revision. Using this approach, you’re less likely to fall into the trap of trying to make your design perfect.

Tools of the Trade

In theory this all sounds great, who doesn't want to build faster and less expensively?

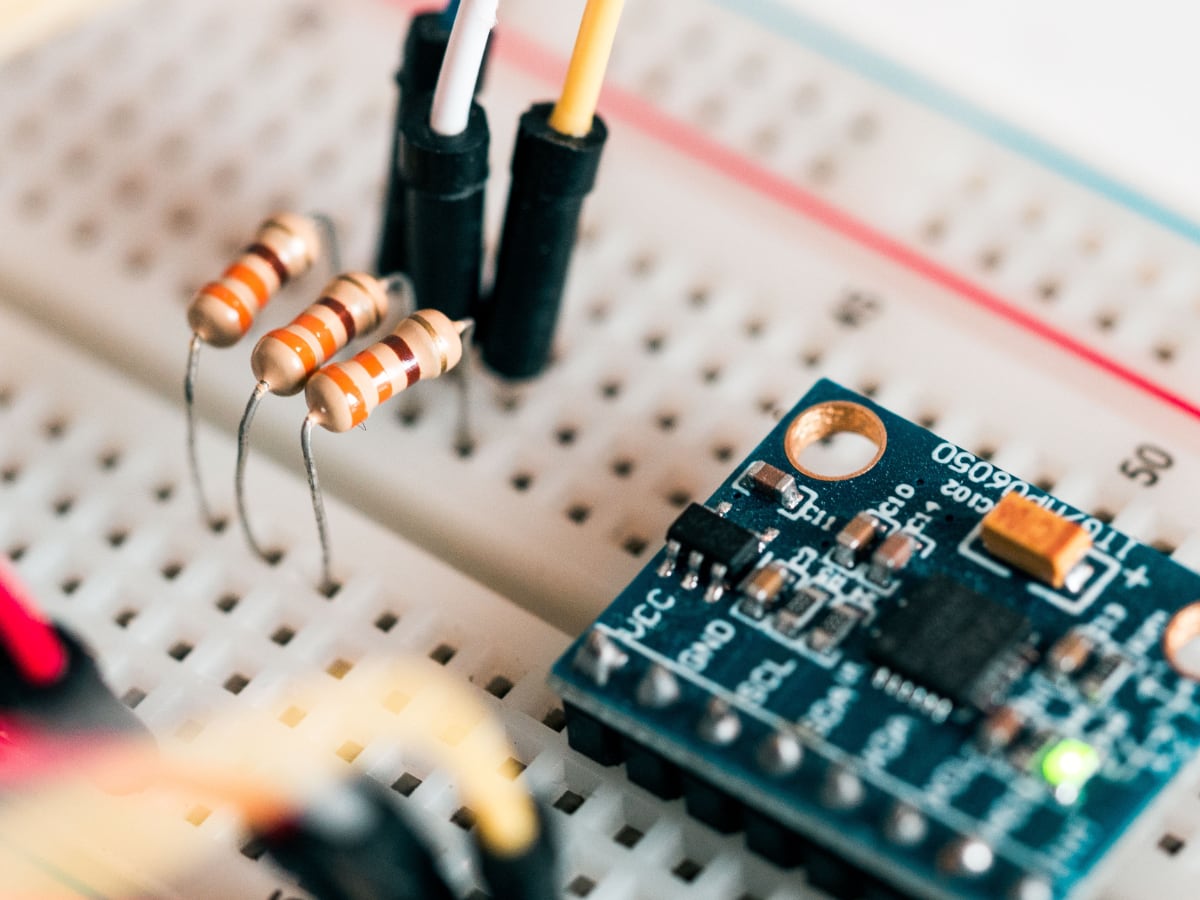

However, to make the method really work for you, you'll want to take advantage of hardware ecosystems that are designed to help early stage design. Adafruit, SparkFun, Seeed, Rak Wireless, and Mikroe all have solutions.

Interestingly, each of these solutions foregoes the breadboard and jumper wires in favor of custom cables that connect between modules in their ecosystems.

Great for quickly adding sensor and actuators

Great for adding more complex modules and systems

Rapid Prototyping == Rapid Results

What you'll find once you begin to prototype with any of these systems is that you're simply faster. Faster at building a working hardware design. Faster at writing the firmware because each module has good library support within their ecosystem. And faster at being able to take the opportunity to review and refine your design.

note

noteBlues Notecarriers use Qwiic/StemmaQT I2C connectors, except for the Notecarrier Pi Hat that uses a Grove connector.

The SparkFun MicroMod Blues Wireless Notecarrier is part of a more complex ecosystem of embedded design prototyping solutions.