While it is easy to get your hands on a Blues Notecard, it's not as easy to learn what it takes to manufacture one. That is... until today.

This post walks you through the factory floor as a panel of Notecards pass through each step of the manufacturing process — going from an unpopulated printed circuit board (PCB) to a working Notecard.

Before the Manufacturing Even Begins

The manufacturing process is the culmination of a huge amount of behind the scenes engineering and operational work. Before a single component is shipped to the manufacturing facility, electrical engineers must finish the PCB design and layout. This information packaged in a Gerber file format, which provides the exact design requirements for the PCB as well as the placement of the components.

Simultaneously to the work of the electrical engineers, operation engineers work with component vendors and suppliers to find the best prices, and component variants for the quantities necessary to successfully manufacture the electrical engineer's design.

It All Starts with Printed Circuit Boards

Notecard PCBs are the first component of the manufacturing process that needs to be manufactured. Using a layering process of copper and FR4—a type of fire-resistant fiberglass—PCBs are built one layer at a time. Advanced PCBs like Notecard's use multiple layers of FR4 and copper to properly connect all of the components necessary to make up the final design.

note

noteScotty from the YouTube channel Strange Parts has a great video tour of the PCB manufacturing process if you're interested in the step-by-step process.

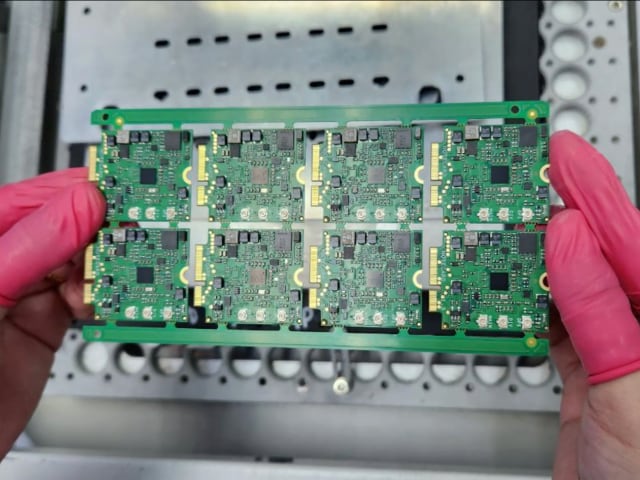

With Notecard manufacturing a panel of eight Notecards is the smallest unit of material that goes through the line. This improves production output while reducing the time that the manufacturing line is operational.

As you can see in the unpopulated panel above, the exterior layer of the Notecard PCB consists of exposed copper pads and green areas of solder mask. Copper when heated will attract solder whereas the solder mask when heated will not.

Application of Solder Paste

The first stop on the manufacturing line is the solder paste machine. The Notecard panel is placed inside the machine and a thin metal stencil is secured over the panel.

An automated squeegee then smears a combination of solder paste and flux across the stencil depositing globs of the gooey material on the exposed copper pads. After a few passes of the squeegee, the stencil is removed and the panel is placed on a conveyer belt bound for the next step of the manufacturing line.

Optical Inspection

Before the manufacturing process goes any farther, a series of high-powered cameras inspect the dollops of solder paste and flux are correctly placed on the copper. Too much or too little solder and flux could be detrimental to the assembly process and potentially create bad solder joints between the PCB and the components.

This early inspection and anomaly detection is just one of the steps meant to ensure production efficiency and reduces costly rework later on in the manufacturing process.

Component Placement on the PCB

With fresh solder paste and flux on the PCB pads, the next step in the assembly process is component placement. It's here at the Pick-and-Place machine that automation is at its most advanced.

All the components that make up Notecard are loaded into the pick-and-place machine. Each component is packaged on a reel that loads into the pick and place machine almost like a printer cartridge to a laser printer.

The pick-and-place machine is programmed to know exactly where each component is stored on a reel as well as where each component must be placed on the PCB panel. Using a suction device on a gantry arm to lift the component and move it into position, the pick-and-place machine is able to precisely select and deposit tens of thousands of components per hour.

The speed and accuracy of these machines boggle the mind. They are simply put the backbone of the modern manufacturing line.

Soldering at Scale

With all the components placed on the globs of solder paste and flux, the only thing holding them in place is surface tension. To make a more permanent connection heat needs to be carefully applied to the panel of Notecards.

Unlike your typical handheld soldering iron where you solder one component at a time, manufacturing lines use reflow ovens to solder all of the components on one side of the PCB at once.

These high-tech ovens precisely modulate the temperature based on temperature curves input by engineers so that they heat up and cool down period is very deliberate and conforms to the temperature tolerances of the materials being reflowed.

When a reflow oven heats up, the solder paste and flux melt. The surface tension of the molten hot solder pulls the SMT component towards the copper pad on the PCB and as the oven temperatures drop, the solder cools and forms a solder joint — an electrical connection between the component and the PCB pad.

Astonishingly, reflow ovens are so precise that they are able to heat one side of a PCB and not melt the solder on the other side of the board. This allows for two-sided boards like Notecard to be reflowed in two passes — one for the top side and one for the bottom side — without any components falling off during the process.

After the solder joints are cooled, the panel of Notecards is conveyed to another automated optical inspection machine.

Automated Optical Inspection

Automated optical inspection at this point in the manufacturing line is focused on ensuring the solder joints and component placement have no defects.

As with the first round of optical inspections, it's far better to catch any problems here before the panel advances to the next stage of manufacturing.

Quality Control with a Human Touch

Quality control is the last stage of the manufacturing process where the eight Notecards are connected on one panel. Rather than rely on automation, this quality control step is performed by a manufacturing engineer.

They perform a visual inspection of all areas of the panel using large magnifying glasses as well as conduct other testing to ensure the Notecards have been properly assembled. Once approved, the panel of Notecards is ready for depanelization.

Depaneling into Single Notecards

Using an advanced router, the depaneling machine uses a bit to remove the excess FR4 material that held the eight Notecards together.

To ensure that the Notecards are not damaged during the process, the panel is loaded into a tray and a fixture is placed over the panel to guide the the router bit as the depanelization occurs.

Notecard Functional Testing

With each Notecard free from its panel and fully populated with components, it's ready for functional testing. This step ensures that the Notecard is able to power on properly and execute a series of test commands.

Once the Notecard passes the functional tests, it's off to the labeling and packaging department.

Individual Packaging and Boxing

Each Notecard is packaged individually inside a zip-locked back and placed into a large tray.

Multiple trays are stacked to snugly fit into larger shipping boxes to optimize the number of Notecards that can fit ship at a time.